Reliance Halts $10B Battery Gigafactory After China Tech Deal Collapses

January 11, 2026 · by Fintool Agent

India's largest conglomerate has quietly abandoned its most ambitious clean energy initiative after Beijing's technology export controls torpedoed a critical partnership—a setback that exposes the limits of even the world's most powerful companies in breaking China's stranglehold on the battery supply chain.

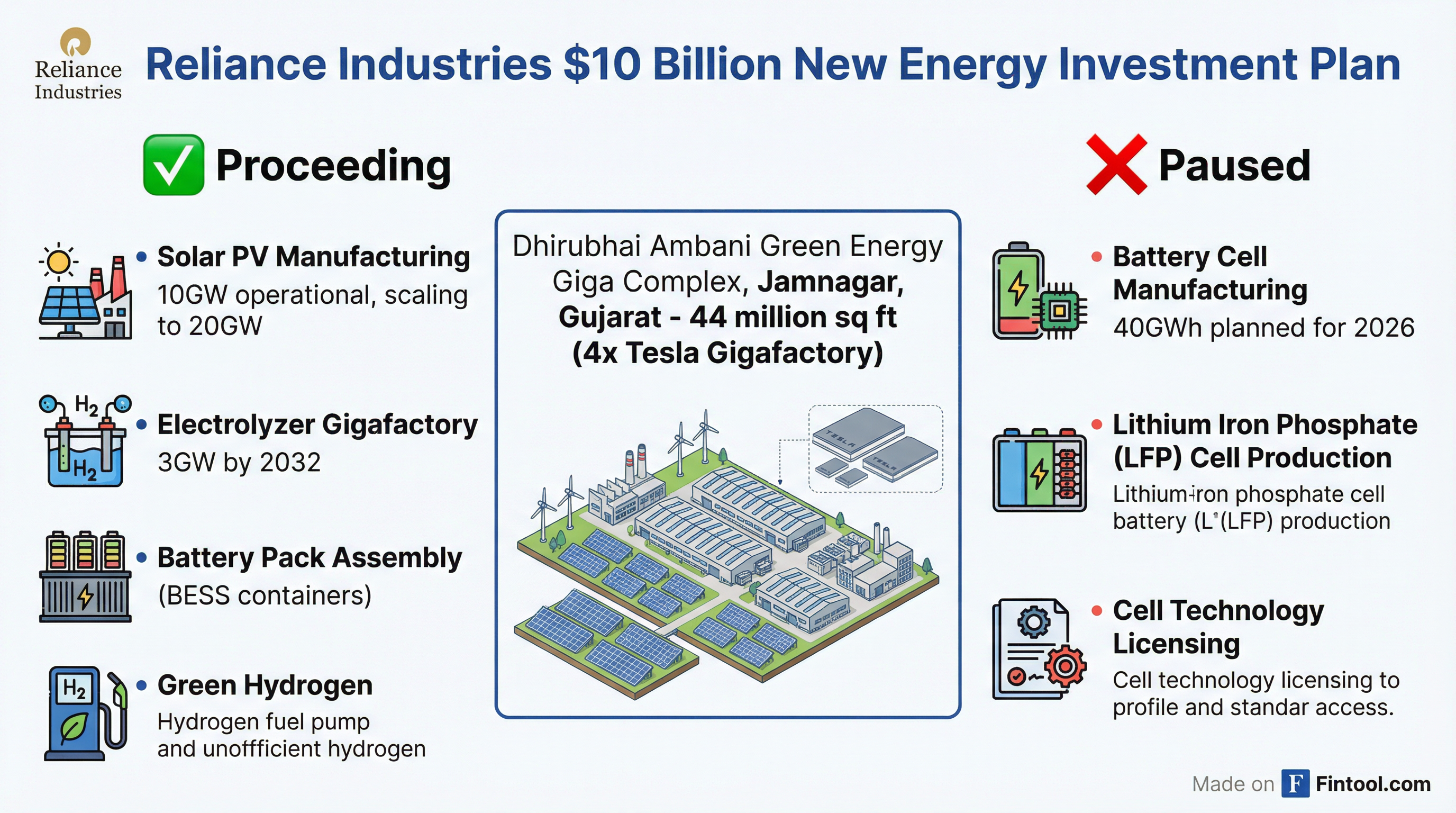

Reliance Industries+0.51% has paused plans to manufacture lithium-ion battery cells in India after failing to secure technology from Xiamen Hithium Energy Storage Technology Co., according to people familiar with the matter. The Mukesh Ambani-led conglomerate, which had targeted beginning cell production in 2026 as part of a $10 billion clean energy investment, is now refocusing on assembling battery energy storage systems instead.

The collapse marks a significant blow to both Reliance's clean energy ambitions and Prime Minister Narendra Modi's goal of making India carbon-zero by 2070.

The Partnership That Fell Apart

Reliance had been in advanced discussions with Xiamen Hithium to license lithium iron phosphate (LFP) cell technology—the dominant chemistry for both electric vehicles and grid storage applications. The talks stalled after Xiamen withdrew following Beijing's October 2025 export controls, which placed restrictions on battery technology transfers to protect China's strategic advantages.

The timing is particularly painful. Just months earlier, at Reliance's August 2025 annual general meeting, Anant Ambani—Mukesh's son and executive director—told shareholders the 40 GWh battery gigafactory would begin operations in 2026, with plans to scale to 100 GWh.

"Reliance will be the world's only fully integrated, self-sufficient new energy company," Anant declared at the meeting. That vision now appears significantly compromised.

Why China Holds the Cards

The setback illustrates just how dominant China has become in battery technology—and how difficult it will be for any nation to build an independent supply chain.

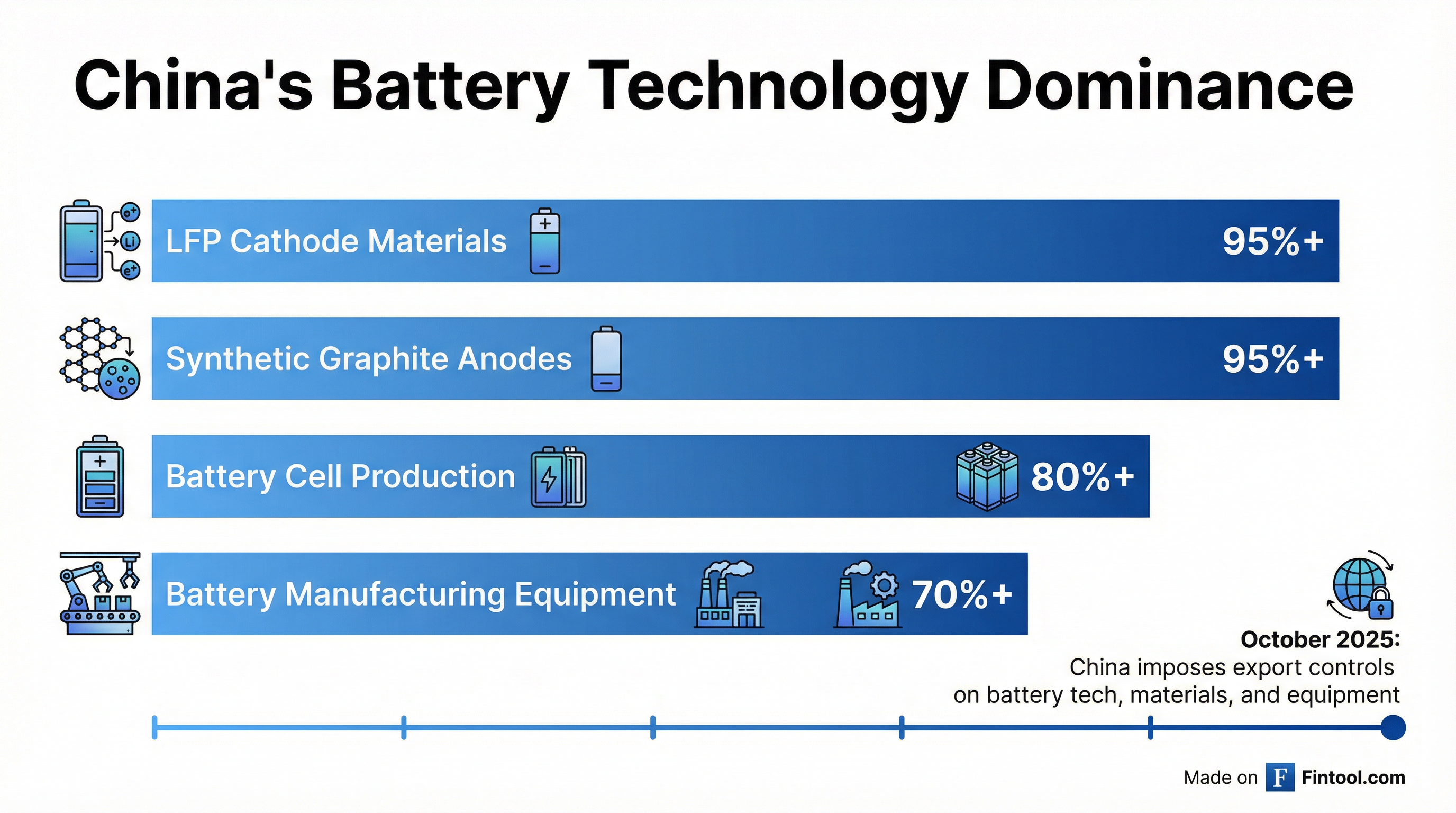

Beijing's October 9, 2025 export controls expanded restrictions to cover:

- High-energy-density lithium-ion batteries (≥300 Wh/kg)

- LFP cathode materials with specific density thresholds

- Precursors for ternary cathode materials

- Artificial graphite anode materials

- Manufacturing equipment and production technologies

China currently controls more than 80% of global battery cell production and over 95% of key materials like synthetic graphite anodes and LFP cathodes.

Reliance's internal teams concluded that proceeding without proven Chinese cell technology would significantly raise costs and execution risks, particularly given global battery overcapacity. Alternative technologies from Japan, Europe, and South Korea were assessed but deemed substantially more expensive and less competitive for large-scale deployment in India.

The $10 Billion Pivot

Reliance's clean energy push—announced at the 2021 AGM—was unprecedented in scale. The Dhirubhai Ambani Green Energy Giga Complex in Jamnagar, Gujarat, spans 44 million square feet of built-up area—four times the size of Tesla's Nevada Gigafactory.

While cell manufacturing is now paused, other elements of the complex continue to advance:

-

Solar PV manufacturing is already operational, producing heterojunction technology (HJT) modules with 10% higher energy yield than standard panels. Reliance plans to scale to 20 GW annual capacity.

-

Electrolyzer manufacturing remains on track for production by end of 2026, with capacity to scale to 3 GW per year for green hydrogen production.

-

Battery energy storage systems (BESS) are now the focus—assembling battery packs and containers for Reliance's renewable projects rather than manufacturing the cells themselves.

Not Just Reliance

The pattern extends across India's corporate elite. Adani Group and JSW Group—both of which have laid out aggressive clean energy expansion plans—are similarly focusing on battery pack and container assembly rather than cell manufacturing.

In November, Gautam Adani announced plans to build a multi-billion-dollar battery energy storage system in western India with 1,126 megawatts of power storage capacity. Notably absent from the announcement: any cell manufacturing component.

JSW has begun operating a 30-megawatt battery energy storage pilot at its Vijayanagar steel plant in Karnataka—for captive use, not cell production.

The hurdles persist despite the recent diplomatic thaw between India and China, as both nations grapple with hefty U.S. import tariffs. Technology transfers remain off the table.

What's at Stake

India's energy storage market is projected to reach approximately 87 gigawatts of power capacity by 2035—more than 300 times what was installed in 2024, according to BloombergNEF.

Without domestic cell manufacturing, India will remain dependent on imported cells for:

- Grid-scale energy storage supporting renewable integration

- Electric vehicle batteries

- Backup power for data centers and telecommunications

Reliance had positioned itself to capture this opportunity through its 2022 production-linked incentive (PLI) award from the Indian government—one of three companies selected to build battery cell plants under a push by New Delhi to cut reliance on imported cells. That PLI timeline now appears unrealistic.

The Geopolitical Backdrop

China's export controls represent a strategic escalation in the global technology competition. The October 2025 measures followed July restrictions on battery cathode material preparation technologies—together forming the most comprehensive restrictions Beijing has imposed on clean energy technology.

The controls have extraterritorial reach: China's regulations allow the Ministry of Commerce to require compliance from overseas entities transferring or providing dual-use items that were produced using Chinese technology or equipment.

For companies like Reliance, the message is clear: building a truly independent battery supply chain will require developing alternative technologies from scratch—a multi-year, multi-billion-dollar endeavor with uncertain outcomes.

What to Watch

-

Reliance's next AGM (August 2026): Will the company announce any alternative technology partnerships or revised battery manufacturing timelines?

-

India's PLI program: Whether the government extends deadlines or modifies incentives given the technology access challenges.

-

Alternative chemistries: Reliance acquired sodium-ion battery technology company Faradion Ltd. in 2022 for £100 million. Sodium-ion doesn't require Chinese-controlled materials—watch for accelerated commercialization announcements.

-

U.S.-China-India dynamics: Further diplomatic progress could potentially ease technology transfer restrictions, though this remains speculative.