America's Graphite Renaissance: After 70 Years of Dormancy, Mining Returns to Challenge China's Battery Stranglehold

December 26, 2025 · by Fintool Agent

The United States hasn't produced meaningful quantities of graphite in seven decades. That's about to change.

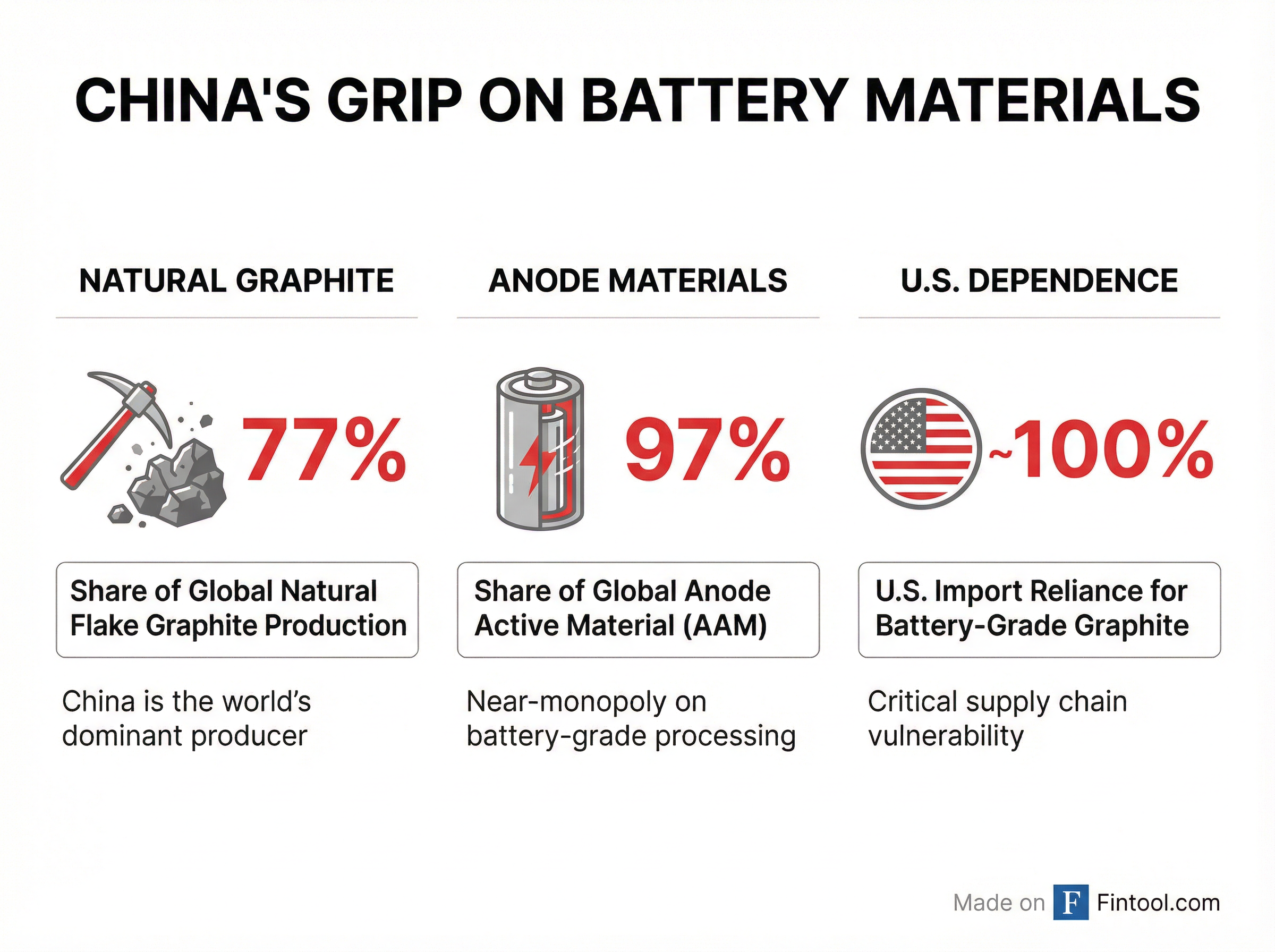

With the battery boom driving graphite demand up 240% by 2034, and China controlling 97% of the world's battery-grade anode material, Washington and private industry are racing to rebuild a domestic supply chain that essentially doesn't exist. The stakes couldn't be higher: without graphite, there are no lithium-ion batteries—and without those batteries, the EV revolution grinds to a halt.

The Vulnerability Is Staggering

The numbers reveal a critical national security risk hiding in plain sight:

The United States is "almost 100% dependent on imports for battery-grade graphite," according to Westwater Resources (WWR), which is building one of the country's first graphite processing plants in Alabama . China supplies approximately 77% of global natural flake graphite and a staggering 97% of global anode active material—the processed graphite that goes into every lithium-ion battery .

This concentration creates what Westwater describes as "significant supply chain management risks, economic risks, geopolitical risks, and environmental sustainability concerns" .

China Weaponizes the Supply Chain

Beijing hasn't been shy about leveraging its dominance. In October 2025, China's Ministry of Commerce imposed sweeping export controls on lithium-ion battery supply chains, effective November 8th. The restrictions cover battery cells, cathode precursors, anode materials, and production equipment—essentially every critical component of battery manufacturing.

While China temporarily suspended stricter verification measures for U.S.-bound graphite shipments until November 2026, the message was clear: supply can be cut at any time.

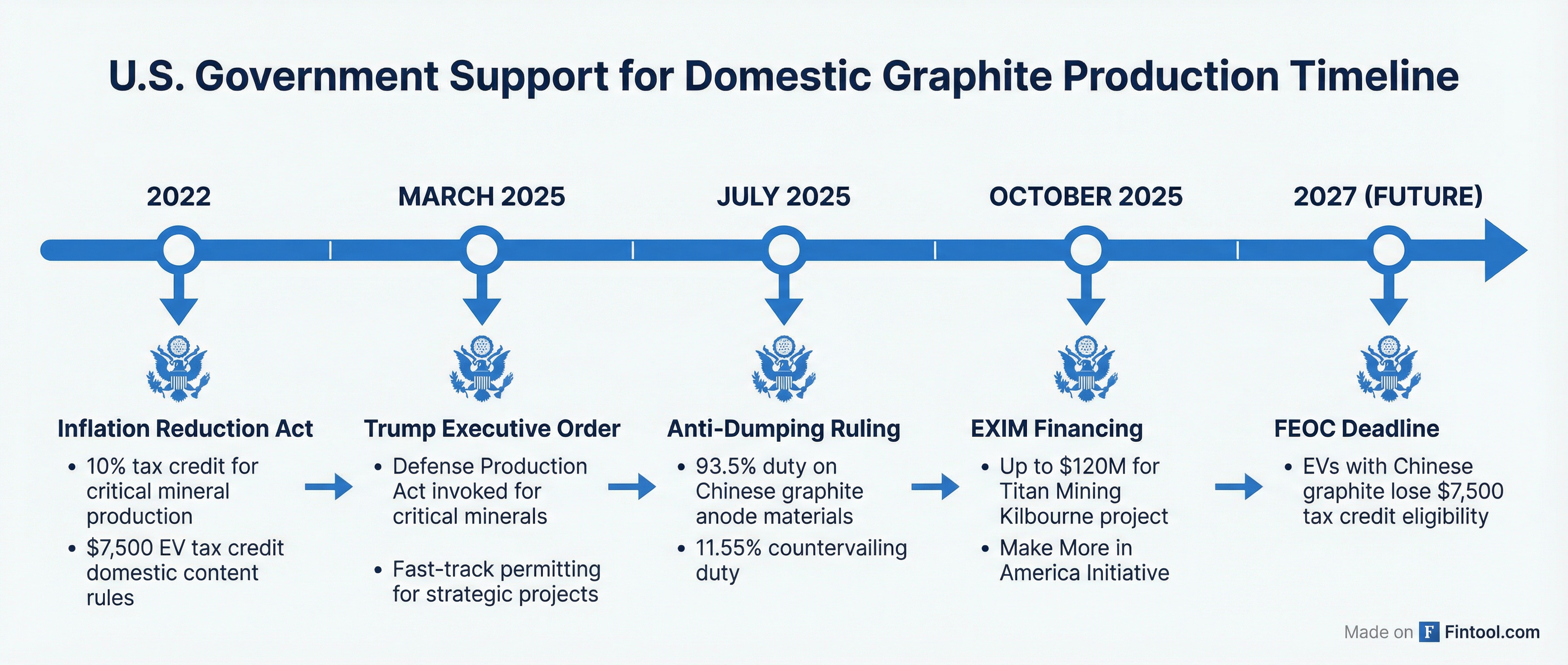

The U.S. has responded with its own trade barriers. In July 2025, the Department of Commerce issued a preliminary anti-dumping duty of 93.5% on Chinese graphite-based anode materials, following a May 2025 countervailing duty of 11.55% .

Washington's All-In Bet

The federal response has been unprecedented. A wave of policy support is now flowing to domestic graphite projects:

Key government actions:

- Inflation Reduction Act (2022): 10% tax credit for critical mineral production, plus Clean Vehicle credit rules requiring domestic content

- Trump Executive Order (March 2025): Invoked the Defense Production Act to accelerate critical mineral production

- FAST-41 Permitting: Graphite projects now qualify for expedited federal review

- EXIM Bank Financing: The Export-Import Bank is deploying capital through its "Make More in America" initiative

The most consequential deadline looms in 2027: starting that year, any electric vehicle whose batteries contain graphite "extracted or processed in any way, and to any degree, by an FEOC—including China—will be ruled ineligible for the federal electric vehicle tax credit" .

The Mining Renaissance Begins

Three projects are leading America's graphite comeback:

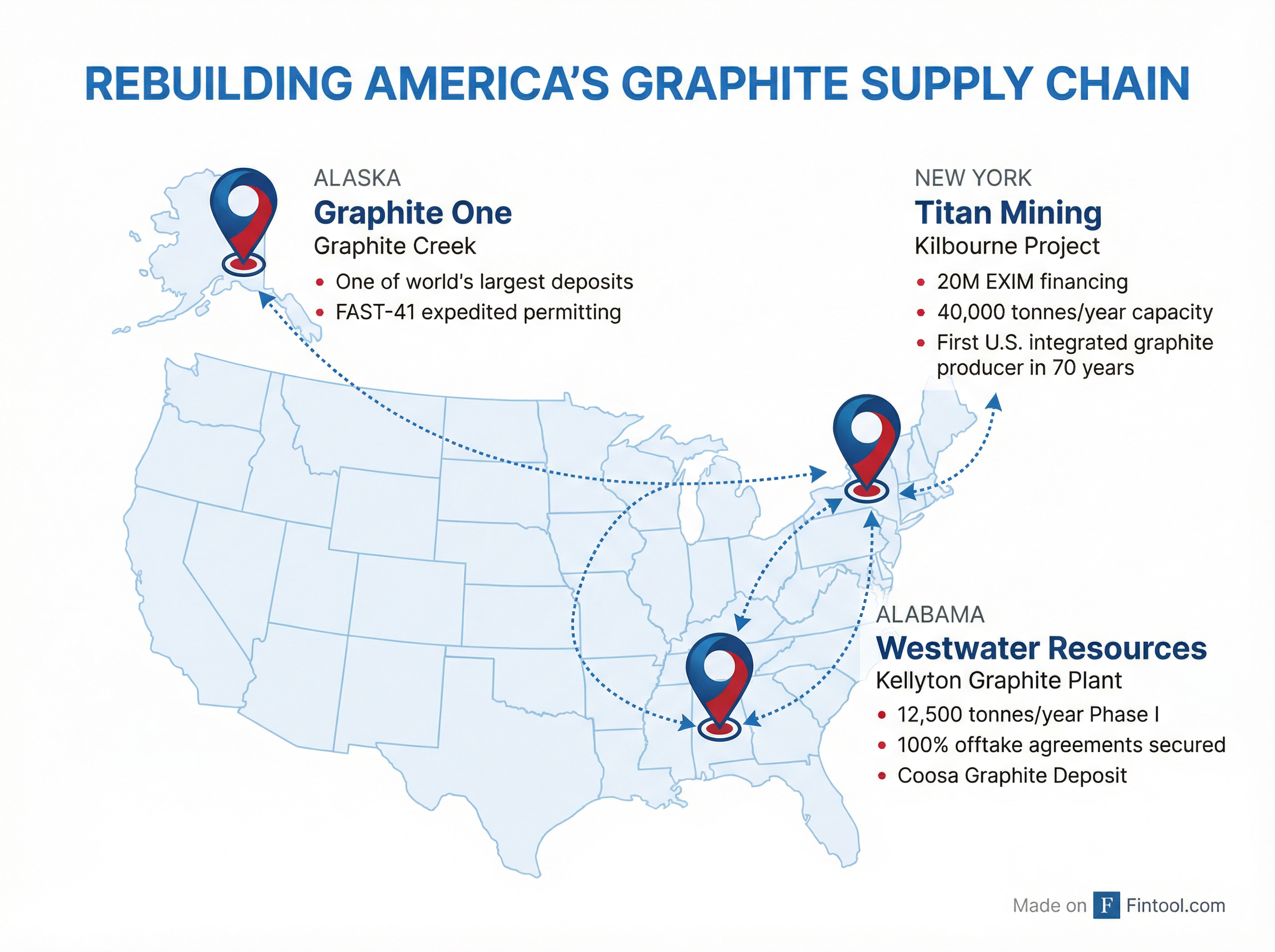

Titan Mining: New York's 70-Year First

Just three days ago, Titan Mining (TSX: TI) closed on the first-ever EXIM Make More in America feasibility financing for a domestic critical-minerals project—$5.5 million to advance its Kilbourne Graphite Project in upstate New York.

The company is targeting 40,000 tonnes per year of commercial natural flake graphite production—positioning itself as "the USA's first end-to-end producer of natural flake graphite in 70 years." EXIM has expressed interest in providing up to $120 million in project financing once feasibility is complete.

"We have the ability to supply a significant portion of U.S. needs," CEO Rita Adiani told the Associated Press. "And that's largely because you can't see China now as a reliable supply-chain partner."

Westwater Resources: Alabama's Processing Pioneer

Westwater Resources is taking a different approach—building processing capability rather than mining. The company's Kellyton Graphite Plant in Alabama is designed to produce 12,500 metric tons per year of coated spherical purified graphite (CSPG) in Phase I, with total construction costs estimated at approximately $271 million .

The strategic positioning is working. Westwater has secured offtake agreements for 100% of its anticipated Phase I production, with "most of these customers and potential customers" being "the largest lithium-ion battery suppliers or vehicle manufacturers in the world" .

The company is experiencing "increased customer interest in Phase II production, which we believe is the result of tariffs and tariff uncertainty and a desire to secure domestic supply of CSPG" .

| Metric | Value |

|---|---|

| Phase I Production | 12,500 mt/year |

| Phase I CapEx | $271 million |

| Offtake Secured | 100% of Phase I |

| Stock Price | $0.83 |

| Market Cap | $72M |

Graphite One: Alaska's Giant

Graphite One (OTC: GPHOF) controls the Graphite Creek property in Alaska—135 mining claims on the Seward Peninsula that the company calls one of the largest known graphite deposits in the world. The federal government this fall approved the project for FAST-41 fast-tracked permitting, calling it a strategic asset that "would build a strategically significant domestic supply chain for graphite."

EXIM has pledged $5.5 million for feasibility studies and indicated it would consider lending up to $120 million for construction.

"When we are sitting with one of the largest graphite deposits in the entire world … there's no reason why we need to rely on China for our graphite," said CEO Anthony Huston.

The Demand Curve Is Relentless

The battery boom is rewriting the graphite market. Global demand for natural flake graphite was approximately 1.9 million tons in 2024 and is projected to reach 4.7 million tons by 2034—a 240% increase driven largely by electric vehicles .

Batteries are expected to comprise 86% of flake graphite demand by 2034, with electric vehicles driving 88% of that battery demand . Graphite is "a critical, currently non-substitutable constituent" in lithium-ion batteries—meaning there's no workaround if supply is disrupted .

Investment Implications

The domestic graphite thesis rests on three pillars:

1. Policy Tailwinds Are Structural The 2027 FEOC deadline creates a hard requirement for non-Chinese graphite in any EV seeking the $7,500 tax credit. This isn't going away regardless of administration changes.

2. Demand Is Mathematically Certain Every EV battery needs graphite anodes. As EV penetration rises, graphite demand follows mechanically.

3. First-Mover Advantage Is Real With offtake agreements already secured and federal financing flowing, the early movers are locking in customers before Chinese alternatives become unavailable.

The risks are equally clear: these are pre-revenue or early-stage companies with significant execution risk. Construction delays, permitting challenges, and technology scaling issues could derail timelines. And if U.S.-China relations thaw meaningfully, the urgency premium could evaporate.

| Company | Ticker | Production Target | Timeline | Federal Support |

|---|---|---|---|---|

| Titan Mining | TSX: TI | 40,000 t/year | 2028 | $125.5M EXIM |

| Westwater | WWR | 12,500 t/year | Phase I in progress | State incentives |

| Graphite One | GPHOF | TBD | Post-feasibility | $125.5M EXIM |

| Nouveau Monde | NMG | TBD | Quebec-based | Canadian support |

What to Watch

Near-term catalysts:

- Titan Mining's Kilbourne Feasibility Study (expected 2026)

- Westwater's Phase I plant commissioning updates

- Final Commerce Department anti-dumping ruling on Chinese graphite

- Any changes to China's temporary export control suspension

Longer-term:

- 2027 FEOC deadline implementation

- Automaker supply chain announcements

- Additional EXIM financing commitments

The graphite renaissance is just beginning. After seven decades of dormancy, American graphite mining is returning—not because of market forces alone, but because geopolitics has made domestic supply a matter of national security.